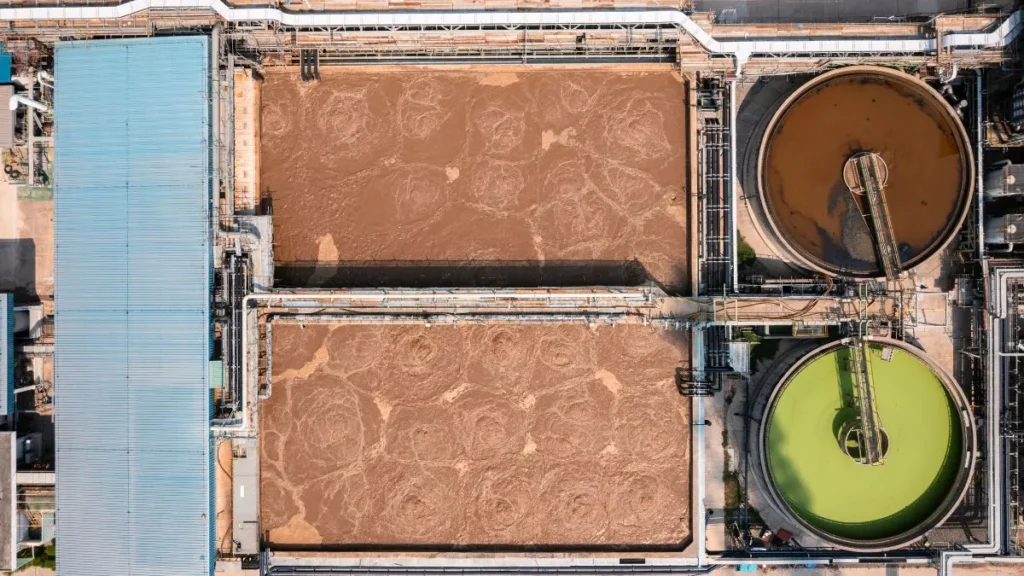

In the water treatment process, be it wastewater or raw water, sludge is one of the by-products that needs to be handled properly. One of the important stages in this sludge management is the sludge thickening process, which is a process to increase the concentration of solids in the sludge by reducing the free water content in it.

Why is Thickening Necessary in Sludge?

Every water treatment process, be it clean water or wastewater, definitely produces sludge as a by-product. This sludge generally contains a large amount of water, making it inefficient if it is directly taken to the dewatering process or final disposal. This is where the importance of the sludge thickening process lies.

1. Reducing Operational and Investment Costs

By reducing the water content in the sludge, the volume of sludge that must be handled in the next stage becomes less. This directly reduces transportation, drying, and disposal costs. In addition, the use of smaller dewatering and drying units can reduce investment costs.

2. Increased Process Efficiency

More concentrated sludge produces higher efficiency when entering the dewatering stage such as a filter press or centrifuge. With a denser consistency, the water separation process becomes more optimal.

Read Also: How to Overcome High Sludge Volume Index (SVI) in Wastewater Treatment

3. Savings on Chemical and Energy Consumption

Innovations in thickening technology have enabled the use of chemicals such as polymers in lower quantities, as well as more efficient consumption of electrical energy. This means reduced raw material costs and operational costs.

4. Space Efficiency and Odor Control

With a more compact system, modern thickener units do not require large spaces. In addition, because the sludge handled is more concentrated and not too liquid, the potential for odor emissions can also be significantly reduced.

Unit Operations in the Sludge Thickening Process

There are several types of unit operations used in the sludge thickening process. Each method has its own characteristics and advantages, depending on the type of sludge handled and the final goal of the processing process.

1. Gravity Thickener

Gravity thickener is the most traditional method in sludge thickening. This system works based on gravity, where solid particles will settle naturally at the bottom of the tank, while water flows out from the top.

Advantages:

- Simple operation and low cost

- Suitable for low concentration sludge

Disadvantages:

- Requires large space

- Retention time is quite long

2. Rotating Sludge Thickener

Is a mechanical version of the gravity thickener. This device is equipped with a rake or rotating arm that helps sedimentation and thickening of the sludge faster.

Advantages:

- Thickening is more efficient than gravity thickener

- Can handle larger volumes of sludge in a smaller space

Disadvantages:

- Higher operational and maintenance costs

3. Dissolved Air Flotation (DAF)

DAF works by injecting air into the sludge, forming microbubbles that stick to solid particles and lift them to the surface. These particles are then collected as a scum layer.

Advantages:

- Effective for sludge with light particles or floc

- Fast processing time

Disadvantages:

- Requires additional energy and chemical consumption

- Higher investment costs

4. Table Thickener

Often referred to as gravity belt thickener, this system uses a porous belt to slowly flow sludge while applying light pressure to remove water from the sludge.

Advantages:

- Suitable for biological or organic sludge

- Continuous operation with small area requirements

Disadvantages:

- Requires routine maintenance on the belt

- Effectiveness is affected by sludge quality

5. Centrifugal Thickener

Uses centrifugal force to separate water and solids in sludge. This machine rotates at high speed so that water is separated from the sludge due to differences in density.

Advantages:

- High efficiency and fast

- Can be controlled automatically

Disadvantages:

- High investment and energy costs

- Requires careful technical control

Read Also: Why is the Activated Sludge in Wastewater Treatment Plant Not Sedimenting Properly?

Professional Support for Your Sludge Thickening Needs

Every water treatment system has its own challenges, including sludge management. That is why Lautan Air Indonesia is here as a partner ready to assist you in finding the most appropriate solution.

With more than four decades of experience in the field of water treatment, we understand the importance of the right approach, not only from a technical perspective, but also in terms of efficiency and long-term sustainability.

We believe that every facility has unique characteristics. Therefore, we offer flexible services that can be tailored to your specific needs, from the initial planning stage to daily operations.

The services we can assist you with include:

- Technical discussions and consultations to help you choose the most appropriate thickener system according to field conditions.

- Procurement of supporting chemicals such as polymers, coagulants, and flocculants to support the performance of the thickening process.

- Periodic operational and maintenance services, including monitoring the performance and efficiency of the thickener unit.

- Technical training for operators, so that the system can be run optimally and safely at all times.

If you are planning to improve the performance of your sludge treatment system or want to consult on the most suitable solution, Lautan Air Indonesia is ready to be your reliable partner.

Contact our team of experts here for more information.