The increasing demand for efficient, sustainable, and environmentally friendly water treatment solutions has brought the spotlight onto the organic coagulant. As industries strive to meet stricter compliance standards and reduce environmental impact, organic coagulants have become a preferred option for both raw water and wastewater treatment.

Benefits of Using Organic Coagulants

Industries across Indonesia are increasingly transitioning to organic coagulants thanks to the significant advantages they offer in operational performance, cost efficiency, and environmental compatibility. Some of the core benefits include.

1. Lower Sludge Volume

Organic coagulants typically generate far less sludge than traditional inorganic coagulants. This reduces disposal costs, simplifies sludge handling, and helps industries meet sustainability targets more easily.

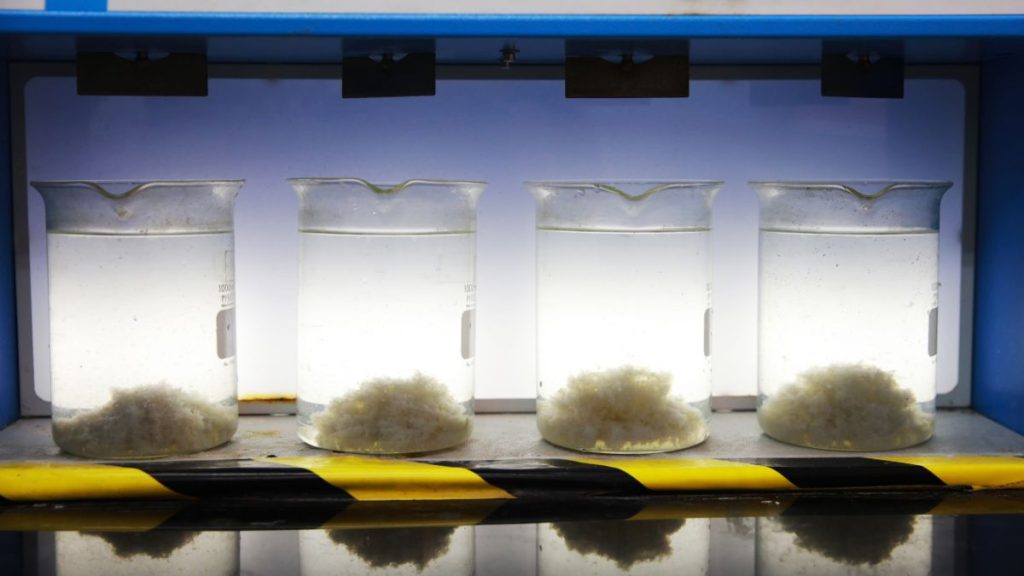

2. Enhanced Water Clarity and Filtration Performance

Organic coagulants often create stronger and more compact flocs, resulting in improved turbidity reduction. This enhances filtration efficiency, increases filter lifespan, and reduces the frequency of backwashing—ultimately lowering operational costs.

3. Lower Chemical Dosage Requirements

Many organic coagulants deliver optimal performance at lower dosing levels compared to inorganic alternatives like alum or PAC. With less chemical consumption, industries benefit from cost savings and reduced chemical storage needs.

4. Better Compatibility with Sensitive Treatment Processes

Because organic coagulants do not leave residual metals in treated water, they are highly compatible with advanced treatment processes such as membrane filtration (UF, NF, RO) or biological treatment systems, where chemical residues can cause fouling or process disruption.

5. Environmentally Friendly Option

Organic coagulants tend to be safer to handle, lower in toxicity, and more aligned with sustainable operational practices. They are increasingly favored by industries adopting greener water management strategies.

6. Stable Performance Across a Wide pH Range

These coagulants maintain their effectiveness even when water quality fluctuates, reducing the need for pH correction chemicals and improving the overall efficiency of the treatment system.

7. Reduced Corrosion and Scaling Risks

Without metal content, organic coagulants help minimize corrosion potential in pipes and reduce scaling issues in downstream equipment—an advantage for long-term infrastructure protection.

Together, these benefits make organic coagulants a reliable and forward-thinking choice for modern water treatment facilities.

Read Also: Scaling and Corrosion in Boilers: A Hidden Threat to Face

Applications of Organic Coagulants

Organic coagulants are used across various stages of water treatment, supporting both industrial and municipal operations. Their versatility allows them to perform effectively in multiple applications, including:

1. Raw Water Treatment

Industries that use surface water or groundwater often rely on organic coagulants to reduce turbidity, remove suspended solids, and improve overall water clarity. Cleaner raw water enhances downstream processes and reduces operational risks in boilers, cooling towers, and membrane systems.

2. Industrial Wastewater Treatment

Many industrial effluents contain high organic loads, color, oils, and fine suspended solids that require robust coagulation. Organic coagulants are widely used in sectors such as textiles, pulp and paper, food and beverage, petrochemical, and palm oil industries due to their strong performance in challenging wastewater conditions.

3. Municipal Water Treatment

Organic coagulants offer safer, low-residual options for municipal drinking water treatment plants. They help achieve excellent turbidity reduction and support the production of clean, safe, and compliant potable water.

4. Sludge Dewatering

In mechanical dewatering systems, organic coagulants improve sludge thickening and enhance water removal efficiency. This results in drier sludge cakes, reduced disposal volume, and lower transportation costs.

Read Also: Sludge Dewatering: Optimizing Efficiency and Environmental Compliance

5. Pre-Treatment for Membrane Systems

Organic coagulants play a critical role in protecting membrane systems from fouling by removing colloids and dissolved organic materials. Improved membrane protection leads to longer membrane life and reduced cleaning frequency.

6. Color and Organic Matter Removal

Industries with colored effluents—such as textile and palm oil processing—use organic coagulants to effectively reduce color and lower organic load prior to discharge or recycling.

With applications spanning raw water, wastewater, and advanced treatment systems, organic coagulants provide reliable solutions for the diverse needs of modern water treatment operations.

Industries That Use Organic Coagulants

Several key industries rely heavily on organic coagulants to meet regulatory standards, improve operational efficiency, and protect equipment. These include:

- Food & Beverage: Ensuring safe water for production processes and managing organic-rich wastewater.

- Textile & Dyeing: Addressing high color intensity and chemical pollutants in wastewater.

- Pulp & Paper: Supporting fiber recovery, color reduction, and wastewater clarification.

- Palm Oil & Agro-Industry: Managing high organic loads and improving discharge quality.

- Municipal Drinking Water Treatment: Providing clean, low-metal coagulant alternatives for potable water.

- Mining & Mineral Processing: Enhancing solid-liquid separation in tailings and process water.

- Petrochemical & Refinery: Handling oily wastewater and complex effluent streams.

The broad adoption of organic coagulants across these sectors is a testament to their effectiveness and adaptability.

Enhance Your Water Treatment Performance with Organic Coagulants

If your operation aims to improve clarity, reduce sludge, lower chemical usage, or adopt more environmentally friendly practices, transitioning to organic coagulants can deliver measurable benefits. Lautan Air Indonesia is ready to support you with high-performance products, expert consultation, and tailored treatment programs.

Contact Lautan Air Indonesia today to explore how our solutions—combined with strong technical service, can optimize your water treatment processes and improve long-term operational efficiency.