In every water treatment process, selecting the best coagulant for water treatment is crucial to achieve clear, stable, and high-quality water output. Whether it’s for industrial, municipal, or commercial use, the right coagulant ensures suspended solids, turbidity, and organic matter are effectively removed.

The ideal coagulant depends on your raw water’s unique characteristics. Choosing the best coagulant for water treatment helps prevent downstream problems like filter clogging, membrane fouling, and inconsistent treated-water quality.

Key Factors to Consider When Choosing the Best Coagulant

Before deciding which coagulant to use, it’s essential to analyze your raw water’s characteristics. Here are the four critical parameters that directly affect coagulant performance.

1. pH Level

The pH of raw water significantly affects coagulant efficiency. Some coagulants work best in slightly acidic conditions, while others remain stable across a wider pH range. If the pH is too low or high, additional chemicals may be required to adjust the condition for optimal coagulation.

2. Turbidity

Turbidity refers to the cloudiness caused by fine suspended particles. High turbidity requires a coagulant with a strong charge neutralization capacity to effectively aggregate particles into larger, settleable flocs.

3. Organic Matter

Natural organic matter (NOM) can consume coagulant molecules and reduce their efficiency. For water sources rich in organics, such as river or peat water, advanced polymeric or blended coagulants are usually recommended.

4. Total Suspended Solids (TSS)

When TSS levels are high, the coagulant must form denser flocs capable of handling heavy particulate loads. Proper selection and dosing will ensure effective sedimentation and filtration downstream.

Read Also: TDS and TSS: Key Differences and How to Manage Them

Comparing Common Coagulants: PAC, ACH, and Alum

Selecting the best coagulant for water treatment often involves comparing different chemical options. Each type offers unique benefits and limitations depending on the water source and treatment goals.

1. Alum (Aluminium Sulfate)

Alum is one of the oldest and most widely used coagulants. It’s cost-effective and reliable, but it works best within a narrow pH range and can produce larger sludge volumes. It’s suitable for relatively clean water with stable characteristics.

Pros: Low cost, widely available.

Cons: High sludge production, limited pH range, higher required dosage.

2. PAC (Polyaluminium Chloride)

PAC has become one of the most popular modern coagulants. It offers stronger performance at lower doses and functions effectively over a broader pH range than alum. PAC also produces less sludge, improving operational efficiency.

Pros: Better turbidity removal, wider pH tolerance, lower residual aluminum.

Cons: Slightly higher cost than alum.

Read Also: PT Lautan Air Indonesia: Leading PAC manufacturer Indonesia

3. ACH (Aluminium Chlorohydrate)

ACH is a more advanced form of PAC with higher basicity and stronger coagulating ability. It provides excellent performance for difficult raw water containing high turbidity or organic load.

Pros: Superior clarification, stable performance, lower sludge formation.

Cons: Higher cost, may require precise dosing control.

How Lautan Air Indonesia Helps You Choose the Best Coagulant for Water Treatment

Lautan Air Indonesia understands that choosing the best coagulant for water treatment requires more than just product selection; it demands data-driven evaluation and technical expertise. That’s why LAI offers a comprehensive range of laboratory and on-site services to ensure clients achieve optimal results.

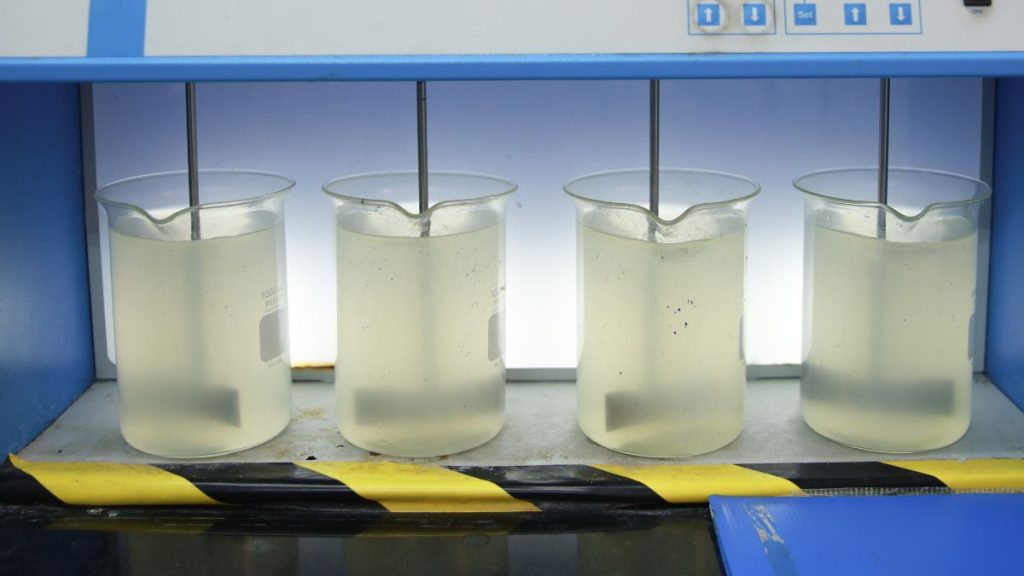

1. Laboratory Analysis and Jar Testing

LAI’s professional laboratory team conducts water quality analysis to identify key parameters such as pH, turbidity, TSS, and organic load. Using jar tests, our specialists simulate coagulation and flocculation at bench scale to determine the most effective coagulant type and dosage for each client.

This scientific approach minimizes trial-and-error and ensures efficient chemical usage, better water clarity, and reduced sludge production.

2. Reliable Coagulant Supply Across Indonesia

With multiple manufacturing plants and distribution centers across Indonesia, LAI guarantees consistent chemical quality and secure supply. We provide various coagulant types, including PAC, ACH, Alum, or customized blends, to meet every water treatment need.

Read Also: Lautan Air Indonesia: Your Reliable Partner and Coagulant Supplier Indonesia

3. Integrated Operation and Maintenance (O&M) Services

Beyond chemical supply, LAI provides operation and maintenance (O&M) services to support daily plant operations. Our experts help optimize dosing systems, monitor coagulation performance, and maintain long-term process stability.

4. Smart Control and Monitoring Support

To enhance reliability, LAI also integrates controller and IoT-based systems that allow real-time monitoring of dosing rates, turbidity levels, and process parameters, ensuring continuous optimization of your coagulation process.

Lautan Air Indonesia Provide Best Coagulant for Water Treatment

Selecting the best coagulant for water treatment requires expertise, precision, and reliable technical support. With more than 40 years of experience, Lautan Air Indonesia delivers end-to-end solutions, from laboratory testing and coagulant selection to operation and maintenance services, ensuring each client achieves consistent and efficient treatment results.

Contact Lautan Air Indonesia today to discuss your water treatment needs. Our specialists are ready to help you identify the most suitable coagulant and implement optimized treatment solutions tailored to your facility.