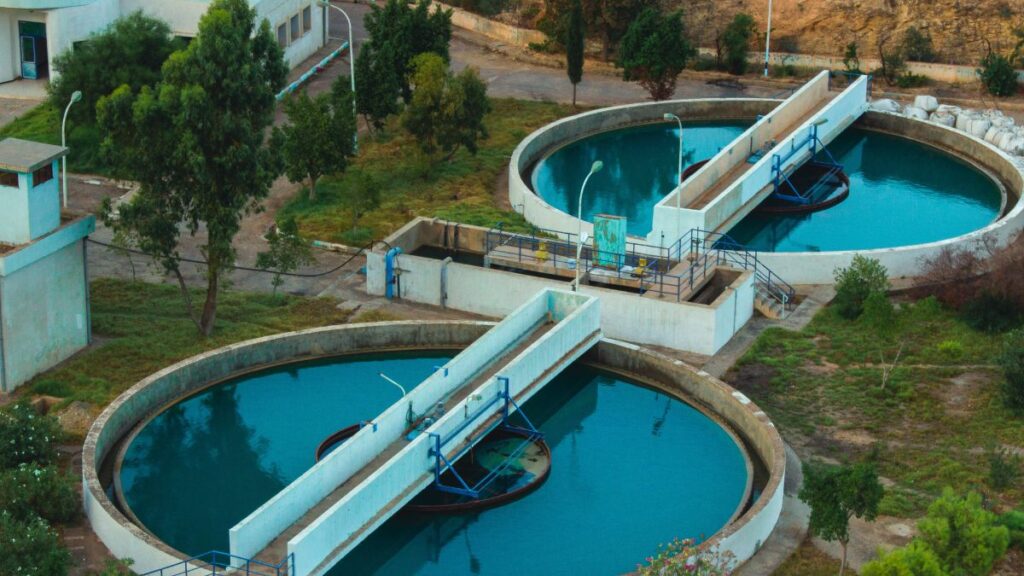

In water treatment systems for both domestic and industrial use, the clarifier plays a critical role in overall process efficiency. A clarifier is a key unit in the initial stage of water treatment and is designed to separate suspended solids from water through a gravity sedimentation process.

Without a properly designed clarifier, solid and liquid separation becomes less effective, requires higher energy input, and can negatively impact downstream processes such as filtration, biological treatment, and disinfection.

What is a Clarifier and How Does It Work?

A clarifier is a water treatment system used to remove suspended solid particles from water or wastewater by slowing down the flow and allowing solids to settle naturally under the influence of gravity.

When raw water or wastewater enters the clarifier, the flow velocity is reduced. Under these conditions, heavier particles settle at the bottom of the tank to form sludge, while clarified water flows out from the top and continues to the next treatment stage.

A clarifier generally consists of several functional zones:

- Inlet Zone: Designed to distribute incoming water evenly and minimize turbulence.

- Settling Zone: The main sedimentation area where suspended solids settle due to gravity.

- Sludge Zone: The area where settled solids accumulate and are collected as sludge.

- Effluent Zone: The section where clarified water exits the system for further treatment.

Clarifiers are widely applied in raw water treatment plants as well as wastewater treatment plants, depending on the characteristics of the water being treated.

Types of Clarifiers in Water Treatment Systems

Clarifiers are commonly classified based on their role in the treatment process. The two most widely used types are primary clarifiers and secondary clarifiers.

1. Primary Clarifier

A primary clarifier is installed at the early stage of wastewater treatment. Its main function is to remove coarse suspended solids and organic matter before biological treatment begins.

At this stage, a primary clarifier can typically reduce:

- 50 to 70 percent of Total Suspended Solids (TSS)

- 25 to 40 percent of Biochemical Oxygen Demand (BOD)

Primary clarifiers are usually circular or rectangular tanks equipped with a sludge collection system at the bottom and surface skimmers to remove fats, oils, and grease.

2. Secondary Clarifier

After biological processes such as aeration, wastewater still contains active biomass in the form of biological sludge. A secondary clarifier separates this biomass from the treated water.

The settled sludge can be returned to the aeration tank as return activated sludge or removed as waste activated sludge.

Secondary clarifiers are designed to ensure efficient separation of microorganisms so that the clarified effluent can proceed to filtration or disinfection.

Read Also: Why Solids Floating in Secondary Clarifiers?

Clarifier Applications Across Industries

Due to their versatility, clarifier systems are used across various sectors, including:

1. Municipal Wastewater Treatment

Clarifiers help maintain treatment stability by reducing organic and solid loads before and after biological processes.

2. Food and Beverage Industry

Used to remove food residues, fats, and organic materials prior to filtration or disinfection.

3. Chemical and Petrochemical Industry

Clarifiers remove heavy solids and chemical residues from process water and wastewater, protecting downstream equipment.

4. Textile and Paper Industry

Applied to separate fibers, dyes, and chemical contaminants before discharge or reuse.

5. Raw Water Treatment

In river and lake water treatment, clarifiers reduce turbidity and TSS, making downstream filtration more effective.

Read Also: Raw Water Treatment System: The Initial Solution for Quality Water

Benefits of Using a Clarifier in Water Treatment

The integration of a clarifier into a water treatment system offers several advantages:

1. Effective turbidity reduction

Suspended solids are removed early, resulting in clearer water.

2. Improved downstream system performance

Filtration, biological, and chemical units operate more efficiently and have a longer service life.

3. Reduced operational costs

Lower chemical consumption and minimized equipment maintenance.

4. Compliance with environmental standards

Helps achieve discharge requirements for TSS, BOD, and COD.

5. Improved process stability

Consistent sludge removal supports reliable system operation.

Improve Clarifier Performance with Lautan Air Indonesia

A clarifier that is not operating optimally can lead to reduced effluent quality, increased operating costs, and potential environmental issues. Proper system design, operation, and maintenance are essential to avoid these risks.

Lautan Air Indonesia supports industries across Indonesia with clarifier solutions backed by more than 40 years of experience in water and wastewater treatment. Our services include technical consultation, system evaluation, and periodic maintenance tailored to your operational needs.

Contact us today to discuss your clarifier system and ensure long-term performance and reliability.